CPQ Implementation: How to Stay Ahead of Potential Risks

CPQ Implementation: How to Stay Ahead of Potential Risks

Mar 8, 2024 12:45:00 AM

3

min read

Why to Choose CPQ Instead of an ERP Variant Configurator

Why to Choose CPQ Instead of an ERP Variant Configurator

Mar 1, 2024 9:52:00 AM

6

min read

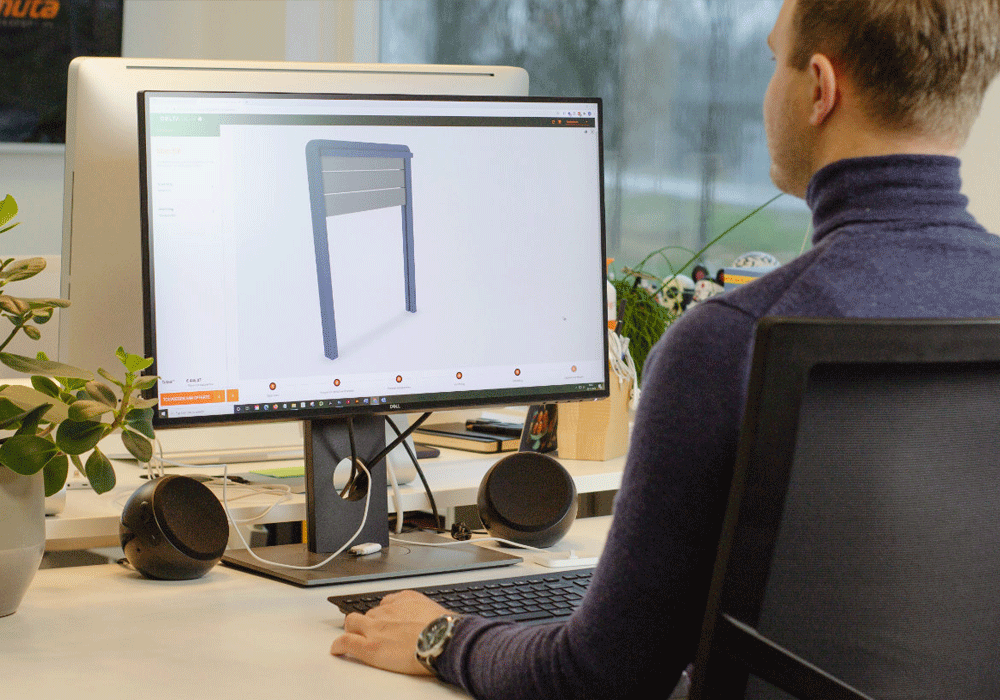

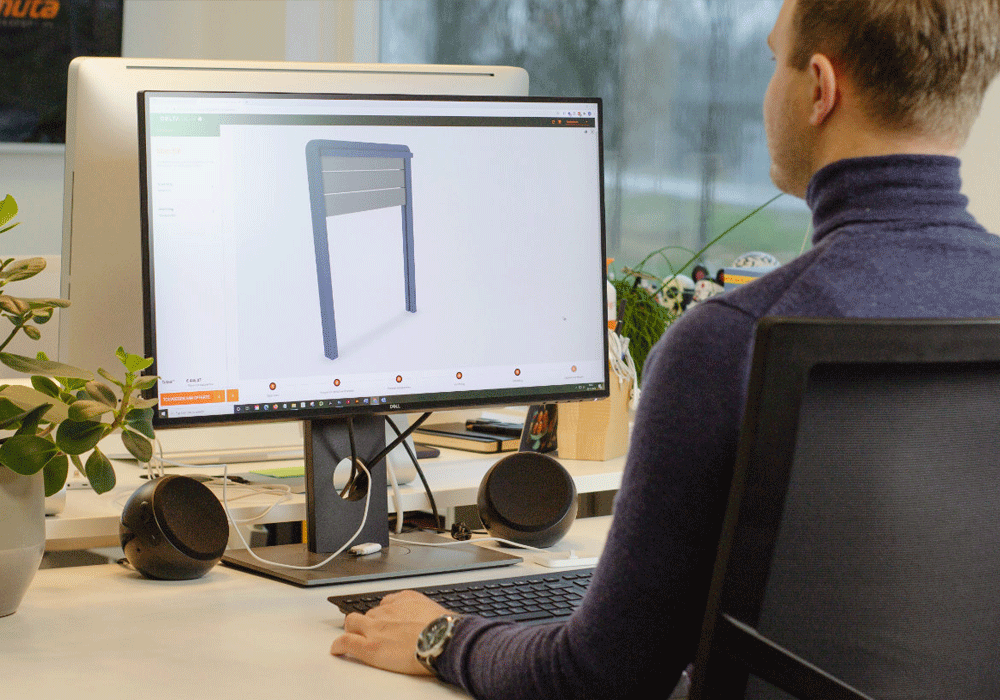

Game Changer in Product Management: PLM & CPQ Integration.

Game Changer in Product Management: PLM & CPQ Integration.

Feb 23, 2024 12:34:00 PM

4

min read

5 Reasons Your CPQ Implementation Fails

5 Reasons Your CPQ Implementation Fails

Feb 16, 2024 12:34:00 PM

5

min read

Omnichannel: Why You Also Want to Be Present Everywhere in B2B

Omnichannel: Why You Also Want to Be Present Everywhere in B2B

Feb 9, 2024 12:35:00 PM

4

min read

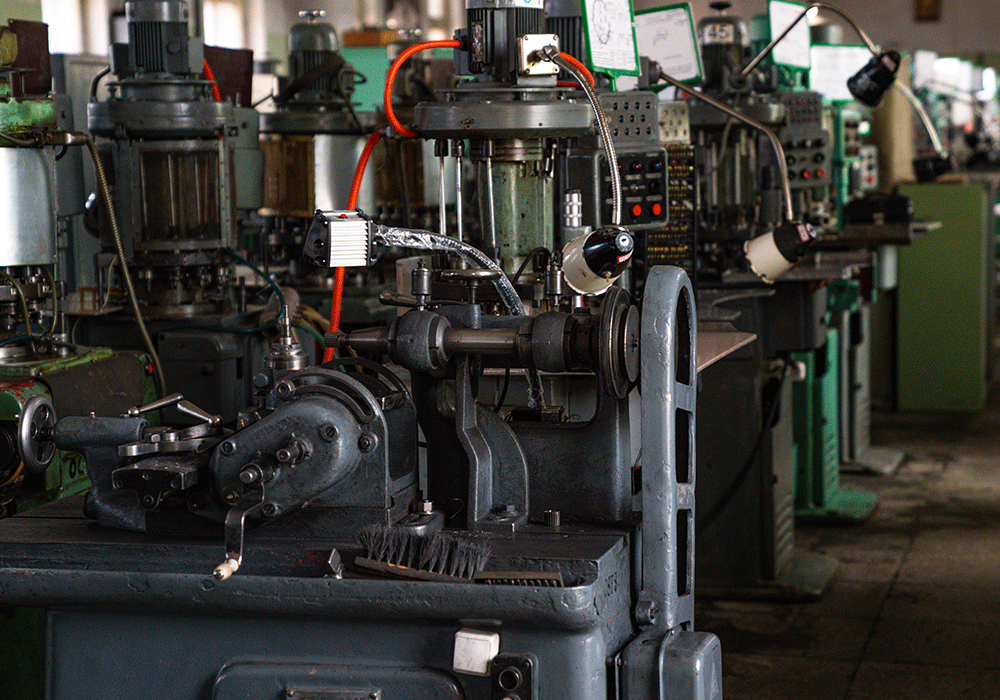

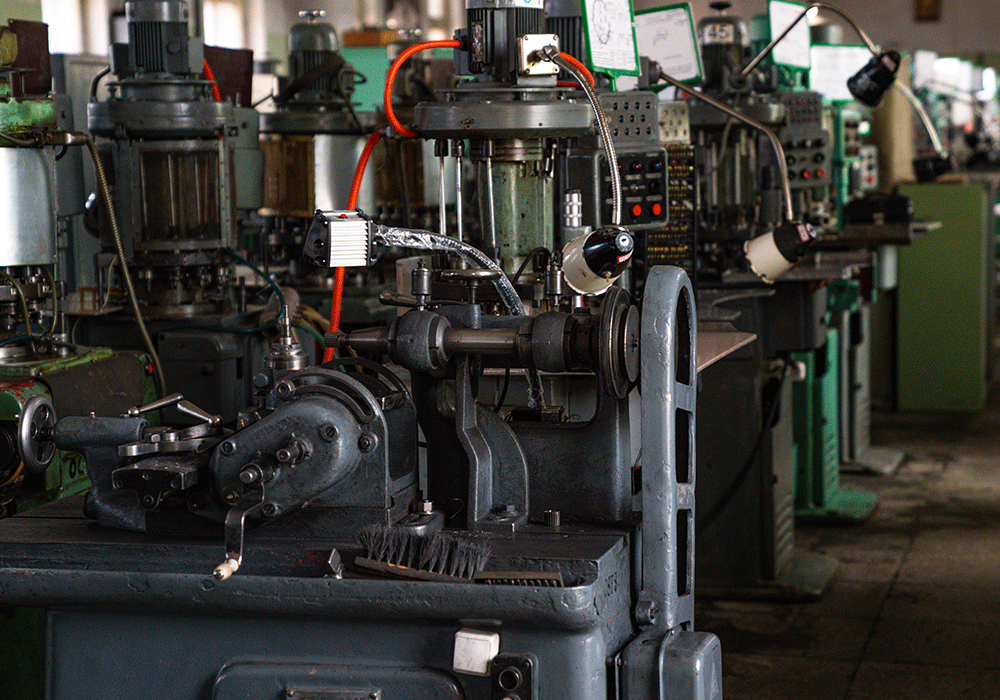

Product Modularity: How Can I Create Modular Products?

Product Modularity: How Can I Create Modular Products?

Feb 6, 2024 12:41:00 PM

2

min read

Benefits of Configure-to-Order

Benefits of Configure-to-Order

Feb 2, 2024 12:35:00 PM

3

min read

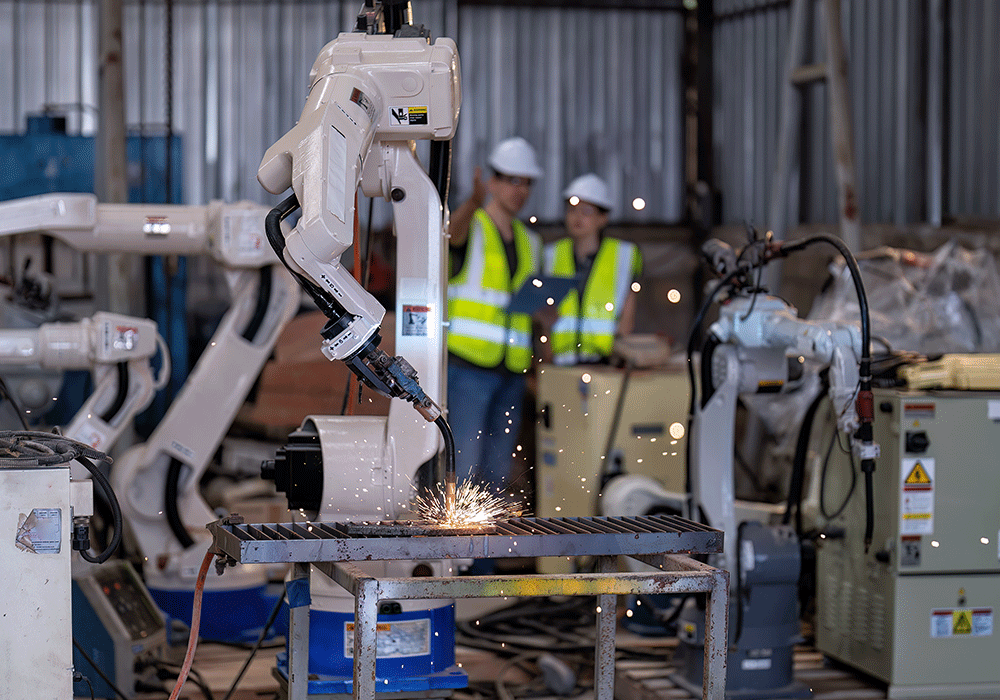

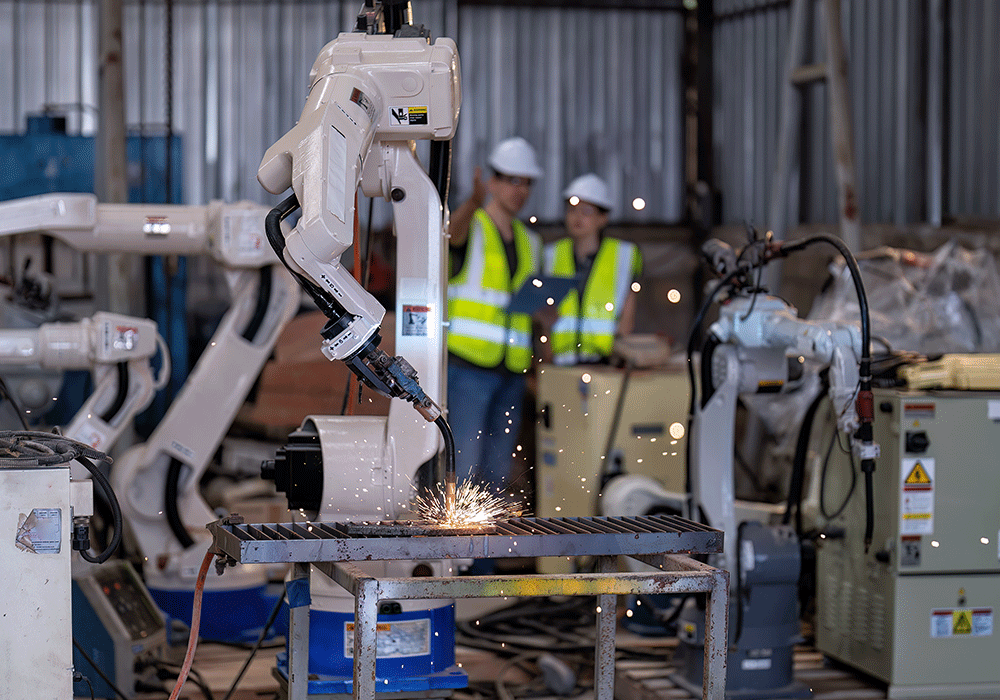

Future of Industry: Everything You Need to Know About Industry 5.0

Future of Industry: Everything You Need to Know About Industry 5.0

Jan 26, 2024 12:36:00 PM

3

min read

World’s Only Product Configurator on the Zapier Platform

World’s Only Product Configurator on the Zapier Platform

Jan 19, 2024 12:37:00 PM

3

min read

Looking for an Open Source Product Configurator?

Looking for an Open Source Product Configurator?

Jan 12, 2024 12:37:00 PM

4

min read