Share this

Game Changer in Product Management: PLM & CPQ Integration.

by Elfsquad on Feb 23, 2024 12:34:00 PM

Product lifecycle management, also commonly known as PLM, is a systematic process for managing the whole lifecycle of a product, from creation to sales, and even end of life.

One of the most important goals for every company is to keep the lifecycle of all products as long as possible, preserving its efficiency. To truly be able to benefit from the product you must ensure its longevity. One of the main reasons for a product to have a predictable lifecycle is to improve its efficiency and profitability. A long efficient product lifecycle saves new product development costs and increases the strength of your brand. To get this cycle to be as long as possible, you have to determine the correct sales strategy.

Just like a living creature, every product goes through the following lifecycle stages: development, introduction, growth, maturity, and decline. This entire process enables the design, analysis, engineering, marketing, and sales branches to be tracked and managed.

More Specifically, What is PLM?

PLM controls the life cycle of companies’ existing products. At the same time, it provides details for the strategies to create new products. PLM automates and helps businesses streamline their product management workflows and production processes. With the added value it provides, it enables an increase in operational efficiency. This is because the guidelines of the product management workflows as well as the execution processes derive from one single source, making it easier to focus.

How to Determine an Efficient Product Lifecycle Strategy?

There is only one way towards the right strategy: meeting the demands of the target market. If your product(s) no longer meets the demand of the customer, the product life cycle is reaching its end. With an operations strategy, you try to align customer expectations, competitive requirements, and your operational resources. You have to start with customer demand and what influences that demand, so you can allocate the right resources and build the most fitting operational strategy. If you don’t meet the exact customer demand, some of your products (or product ideas/developments) already start to decline at the beginning of the lifecycle. Competition in the market directly affects this. If you don’t meet the demands of your customers, you cannot enable correct product management.

Why Isn’t PLM Enough for Your Business?

The most fundamental problem in product management: incomplete or incorrect data flows between your sales, R&D, and production departments. This problem complicates product management and leads companies to errors. The production team has ERP, the sales team has CRM, and R&D has PLM. Data transmissions from CRM and ERP must be correct for your PLM system to work properly. Because if you don’t bring forth and collect CAD drawings, part and component details of your products, and the requested order quantity, you cannot provide product lifecycle management. These details are crucial.

Although CRM, ERP, and PLM are different processes, they should work in harmony with each other. As you want your different teams to work in sync, these structures should work in the same way. We know that this question comes directly to your mind: “How can I integrate ERP, PLM, and CRM systems to meet my customer’s demands?” CPQ software is the answer! With the right integrations, the advantages of CPQ software will increase efficiency in your product management.

What is CPQ, and How Does It Integrate with Product Management?

We know that there are tens, hundreds, maybe even thousands of different parameters for your products. Think of color details or mechanical parts. You may be keeping these parameters and all the details of the products in your PLM system. Because you have your product development team in place to further develop your product. You have two purposes for keeping this information:

- To present the accurate details of your products to your customers,

- To meet the product demanded by your customers by choosing from these details or to develop a new product.

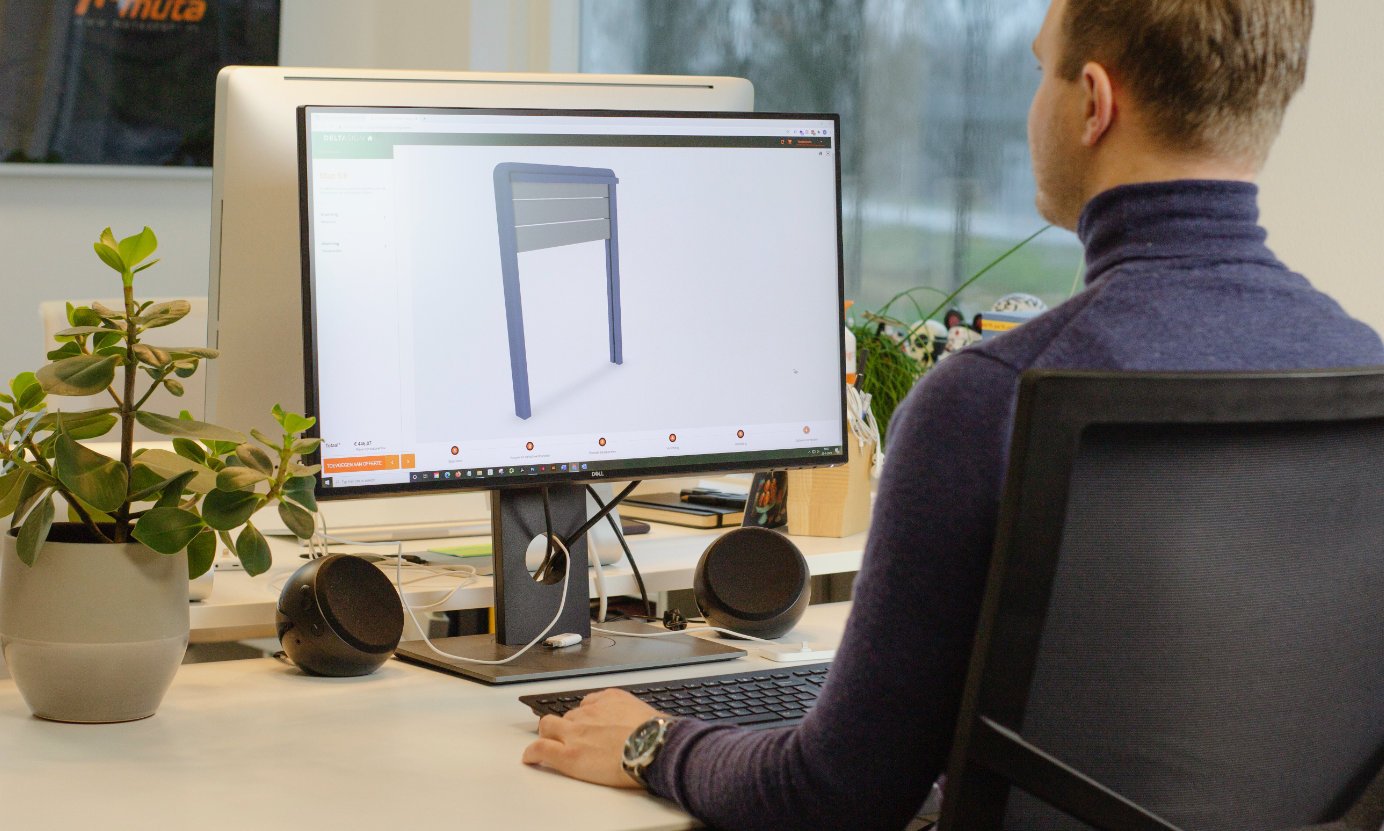

You can either share these parameters directly with your customers or present them through your sales team or dealer network with CPQ software. You will understand and correctly meet the demands of your customers if you present the right data. It’s possible to achieve these with CPQ and PLM integration. You will see how efficient it is to use your PLM data along with guided selling.

Separated Software Systems

As we mentioned above, every team has different needs and different software they use. Companies use many different types of software made up of three-letter abbreviations: ERP, PLM, CAD, CRM, CPQ, PDM… Technology turns into a nightmare whenever these different types of software cannot be integrated.

All of these software systems support some part of the business processes. If your IT teams cannot integrate software properly, the product management process becomes difficult.

At Elfsquad, we have the solution to this nightmare for software developers. You want to integrate in a few clicks. You don’t want to hire a consultant to create your integrations. You want to be in control. Our CPQ software offers the best solution for your software developers. We comply with the OpenAPI standard. You may already know that you can easily integrate Elfsquad with more than 3.000 professional applications. That’s the way to go.