Cellro halves work preparation time with a 100% correct story

Since about half a year, Cellro has happily joined Elfsquad and frequently uses our software. As such, the question to document their experiences and results with Elfsquad Product Configurator was answered with a convincing ‘yes’. Bram de Koning (Product Manager) and Elise de Koning (Marketing Manager) sat down with us to explain the necessity of a configurator. A configurator that eventually halved Cellro’s work preparation time and is able to bring ready knowledge along with everything concerning the current state of affairs to any customer.

Cellro is a Dutch manufacturer of robot automatization solutions (robot cells) for the machining industry. The producer from Veenendaal originates from practise. The challenges found at another business belonging to the same owner, flexibly automating very small series of different kinds of products, turned out to be a recurring question for a lot of machining businesses. A challenge that Cellro took on. Using smart automating systems Cellro answers the growing demand for technical employees in the machining industry, an industry where more technical knowledge goes out than in. As a result, Cellro is one of the biggest pioneers of the automation revolution in their market. Elise de Koning: “By employing these kinds of hardworking and smart automated ‘coworkers’ we gain more time for monitoring and optimizing our customers’ production process.”.

Bram de Koning adds: “We originate in the machining industry ourselves. As a result, everyone is passionate about the market and the product. In turn, everyone strives for a high level. We are not just any integrator on the corner of the street anymore, but a producer of standardized products. We now work with more than 50 employees and an international dealer network, to create robotic automating cells of very high quality and service.”

The complexity

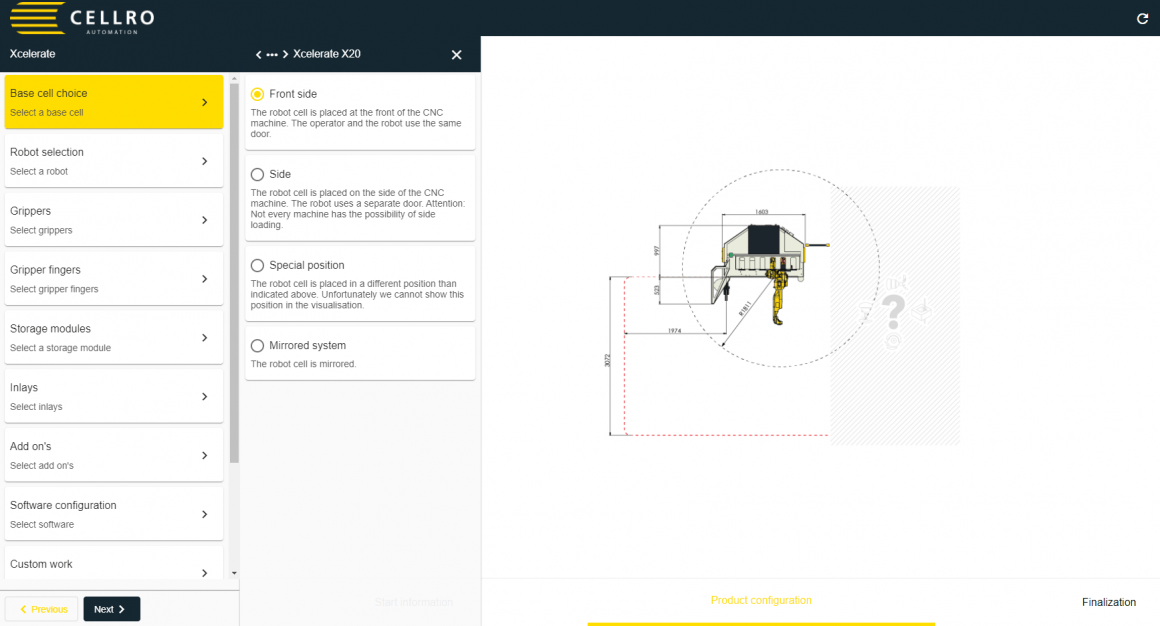

Cellro’s product offer consists of 4 head products, where the Xcelerate has the highest sales market at this moment. The technical elements of these products are substantial. Cellro’s robot automation machines do not limit themselves to automating one of their customers’ machines. Instead, Xcelerate for instance is moveable and can operate up to four machines. Additionally, more processes can be automated; such as milling, spinning, and sharpening. This requires additional functions such as product- and pallet handling. Next to this application the robot cell should not only gain a spot in the machine park but also be integrated in the customer’s production process.

Necessity for a product configurator

There are multiple clear motives leading to the necessity of a configurator for Cellro, to name 3:

1. Creating a scalable sales- and dealer channel.

2. Securing technical product knowledge.

3. Realizing 100% standardization.

Creating a scalable sales- and dealer channel

In the past, Cellro developed a product configurator with a third party. Yet, they very quickly ran into scaling problems: “We built a different configurator. In combination with a company we did a lot of marketing activities with. This was mostly as a focus on lead generation. But a configurator serves a different purpose when you focus on 100% standardization. And requires different design and functionalities. Especially because we wanted to build and manage the tool ourselves.”

The quotation document is generated after completing configuration. The customer gains a nice, complete quotation filled with all of the product’s technical details. And it’s always correct.

Cellro has seen fast growth in the recent decennia, and from their own experience recognizes the necessity of scalable software: “Eventually, we wanted to be able to store all information in a configurator. Not just internally; our external dealer network should also be connected. You want to be able to build your own products, while having control regarding dealers’ rights. Constantly having to supply input to a third party costs too much time in communication.”

Securing technical product knowledge

It’s clear that Cellro’s robot cells require deep technical knowledge. This knowledge is distinctive and that can be problematic: The knowledge of sales, product development and engineering should be secured. We often train our employees internally to keep everyone up-to-date. But preferably this knowledge is documented digitally, available for all of your colleagues. That way, we keep our current employees’ knowledge level up to date, new employees require less training, and knowledge is consistent throughout the organization. Not just for ourselves, but especially for the dealer channels that aren’t working with robotic automating products on the daily. For that reason, securing knowledge is essential to send involved salespeople on their way armed with the most recent developments or product knowledge.”

Realizing 100% standardization

Cellro has been aiming for 100% standardization for quite some time: “A configurator forces you to finetune your standardization and makes things very much black-and-white. A big advantage when looking at product development.”, De Koning explains.

Cellro tells a 100% correct story

“We always want to convey a 100% correct story to the customer. A configurator helps enormously.”, Bram de Koning tells us. Cellro wants to explain the product to the customer with a simpler story. To do this, Cellro uses 2D visualization during the first customer contact, a clear and convincing quotation and a rich information document with additional project information.

2D visualization

Despite the possibility to employ 3D models in Elfsquad Product Configurator, Cellro chooses 2D visualization. Cellro equips the configurator with clear top-view visualizations that can be reviewed with every choice that is made within the configurator. “Despite it being quite intuitive to design Elfsquad with our 3D CAD models, our customer values top-views with corresponding formats and dimensions. Often, questions such as “How does the robot cell fit in my machine park” or “Do I have enough room to move near the cell?” arise. In turn, we will immediately have correct answers at the ready, allowing our salespeople to tell the customer a specific and visual story.”

A configurator forces you to finetune your standardization. Salespeople present a visual and correct pitch to the customer. And the time we used to lose to work preparation must have been cut in half so far.

Bram de Koning Jr.

Product Manager

Powerful answers from Elfsquad

The implementation process has started off with mutual enthusiasm for each other’s product and, and the belief that Cellro can make big steps with the configurator: “We had very specific questions as we already had experience with a configurator partially developed by ourselves. But as a response to these questions we gained powerful answers from Elfsquad. And that impressed us.”, Bram de Koning says.

The implementation process started off very practically, in a way that Elfsquad loves to work. De Koning: “During the first explanation our product was directly composed in a few clicks, and we immediately started building our configuration models. The day after, we went to work with it ourselves and it was clear to us that the choice had been made.”