Doing nothing is also a choice (and the most expensive one you can make)

Doing nothing is also a choice (and the most expensive one you can make)

Jun 16, 2025 5:37:00 PM

3

min read

From Firefighting to a Streamlined Process with CPQ

From Firefighting to a Streamlined Process with CPQ

Jun 12, 2025 2:18:05 PM

2

min read

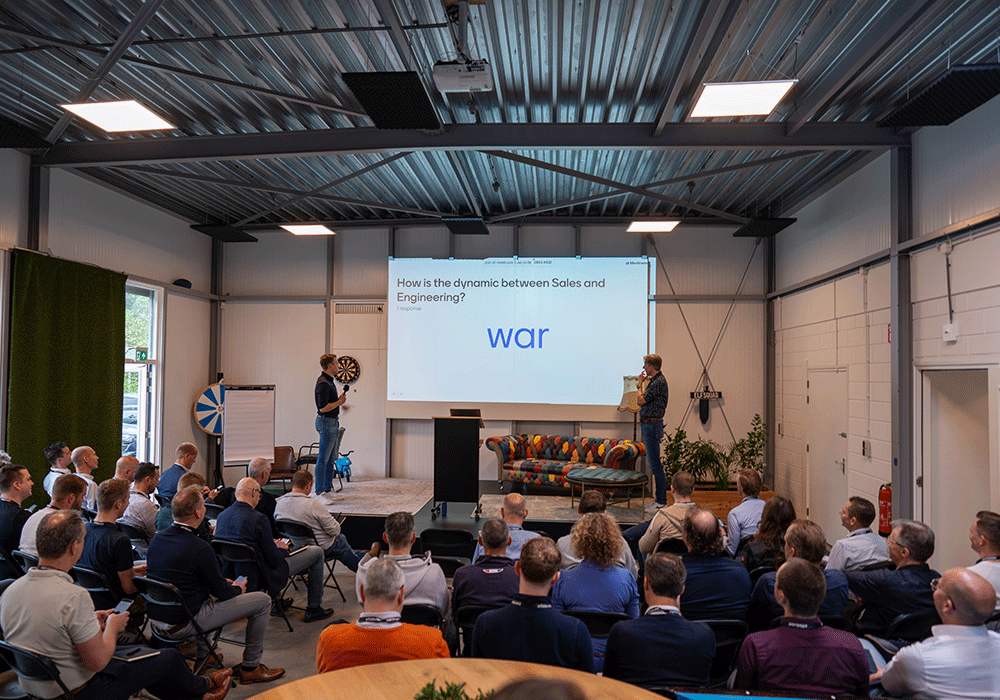

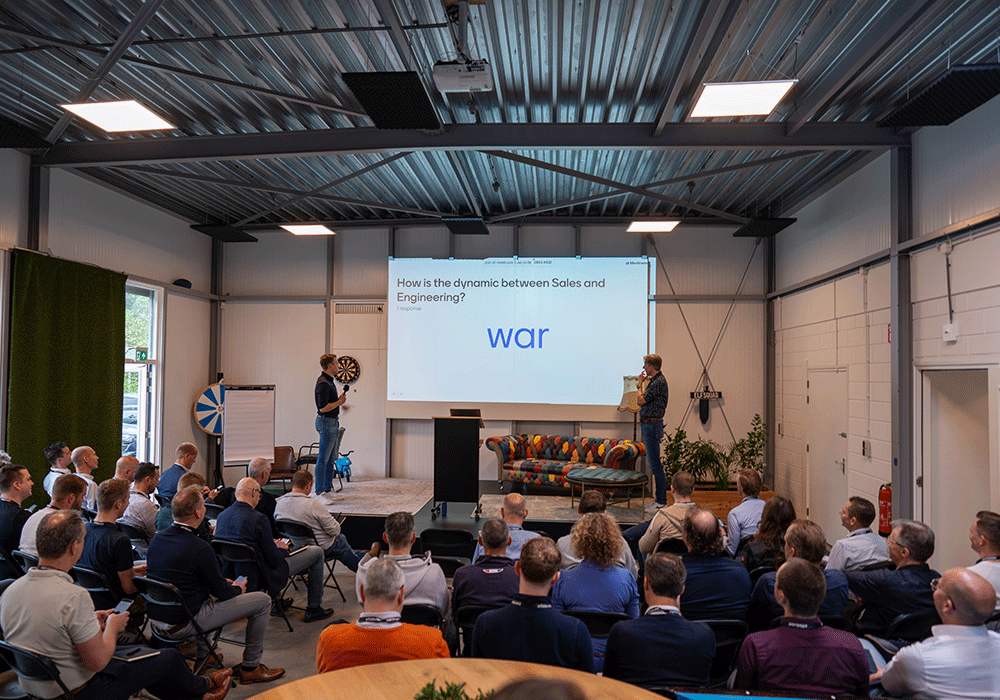

Configure-To-Order: Can It Make Sales and Engineering Friends Again?

Configure-To-Order: Can It Make Sales and Engineering Friends Again?

Jun 3, 2024 9:53:24 AM

4

min read

CPQ Implementation: How to Create the Perfect Project Team

CPQ Implementation: How to Create the Perfect Project Team

May 30, 2024 10:08:06 AM

7

min read

Understanding the Need for Constraint-Based Configurations

Understanding the Need for Constraint-Based Configurations

May 29, 2024 2:45:59 PM

8

min read

A Comprehensive Guide to CPQ Software Selection

A Comprehensive Guide to CPQ Software Selection

May 14, 2024 11:12:12 AM

5

min read

Product Modularity: How Can I Create Modular Products?

Product Modularity: How Can I Create Modular Products?

Apr 2, 2024 10:33:00 AM

2

min read

CPQ Implementation: How to Stay Ahead of Potential Risks

CPQ Implementation: How to Stay Ahead of Potential Risks

Mar 8, 2024 12:45:00 AM

3

min read

Why to Choose CPQ Instead of an ERP Variant Configurator

Why to Choose CPQ Instead of an ERP Variant Configurator

Mar 1, 2024 9:52:00 AM

6

min read

Game Changer in Product Management: PLM & CPQ Integration.

Game Changer in Product Management: PLM & CPQ Integration.

Feb 23, 2024 12:34:00 PM

4

min read

5 Reasons Your CPQ Implementation Fails

5 Reasons Your CPQ Implementation Fails

Feb 16, 2024 12:34:00 PM

5

min read

Omnichannel: Why You Also Want to Be Present Everywhere in B2B

Omnichannel: Why You Also Want to Be Present Everywhere in B2B

Feb 9, 2024 12:35:00 PM

4

min read

Benefits of Configure-to-Order

Benefits of Configure-to-Order

Feb 2, 2024 12:35:00 PM

3

min read

Future of Industry: Everything You Need to Know About Industry 5.0

Future of Industry: Everything You Need to Know About Industry 5.0

Jan 26, 2024 12:36:00 PM

3

min read

World’s Only Product Configurator on the Zapier Platform

World’s Only Product Configurator on the Zapier Platform

Jan 19, 2024 12:37:00 PM

3

min read

Looking for an Open Source Product Configurator?

Looking for an Open Source Product Configurator?

Jan 12, 2024 12:37:00 PM

4

min read

Quote-to-Cash (QTC) vs Lead-to-Cash (LTC): Next Level Pre-Production

Quote-to-Cash (QTC) vs Lead-to-Cash (LTC): Next Level Pre-Production

Jan 5, 2024 12:39:00 PM

5

min read

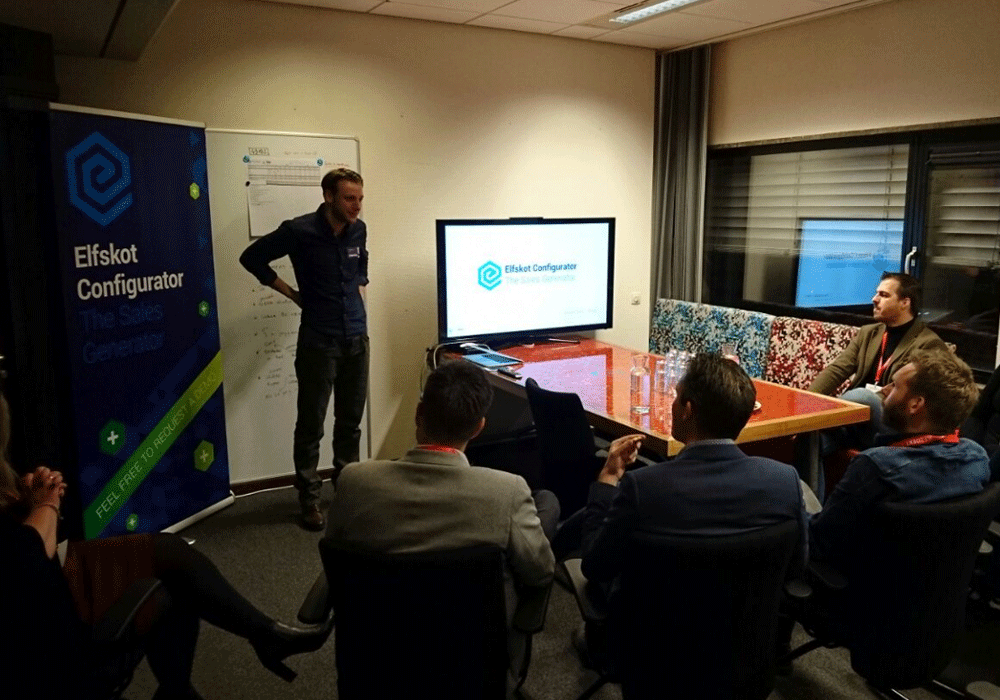

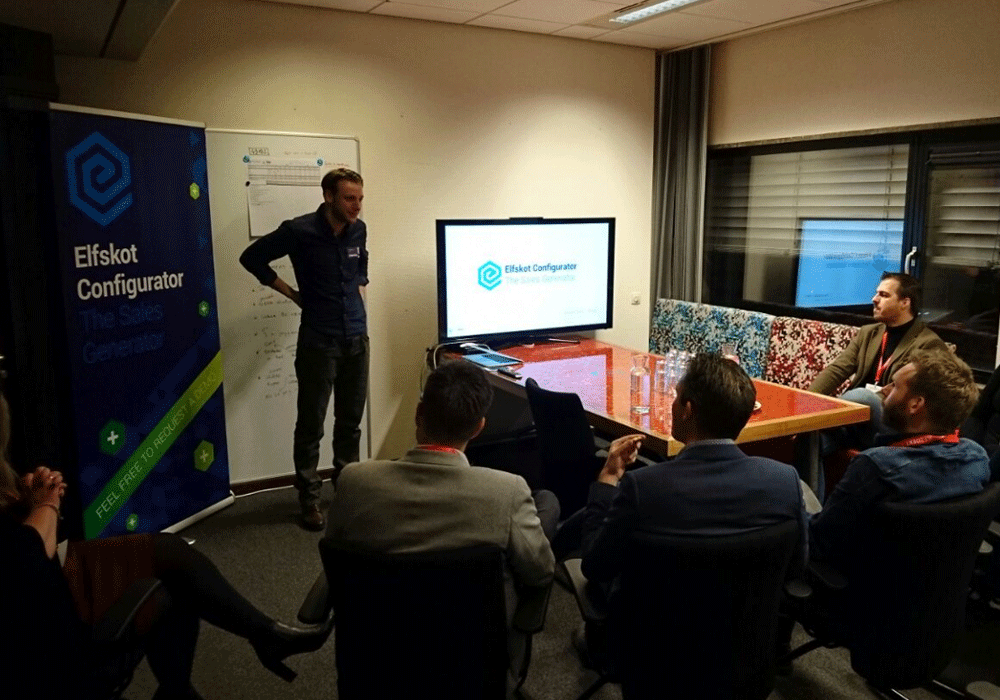

The Story Behind Elfsquad

The Story Behind Elfsquad

Dec 29, 2023 12:00:00 AM

5

min read